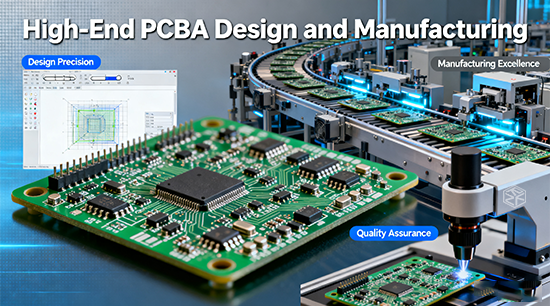

High-End PCBA Design & Manufacturing: Core Technologies, Processes & Selection Guide

High-End PCBA Design and Manufacturing

High-End PCBA (Printed Circuit Board Assembly) Design and Manufacturing represents the pinnacle of electronic industry technology, focusing on achieving ultimate performance, reliability, and signal integrity. It transcends basic connectivity functions, serving applications with stringent demands on computational accuracy, operational stability, and lifecycle—such as aerospace, advanced medical devices, data centers, autonomous driving, and advanced communication equipment—through system-level co-design, precision engineering, and rigorous process control. Its core value lies in transforming complex circuit designs into physical entities capable of long-term, reliable, and efficient operation under actual working conditions.

Core Design and Engineering Considerations

Successful high-end PCBA starts with a forward-looking, multi-physics collaborative design phase:

1.System-Level Architecture & Co-Design: Deep collaboration with IC, mechanical, thermal, and firmware/software teams from the outset to plan for power integrity, signal integrity, thermal management, and EMC.

2.Advanced PCB Design: Utilizes high-layer-count boards (often 12+ layers), HDI (High-Density Interconnect) technology, any-layer vias, and back-drilling. Strict impedance control (typically with ±5% or better tolerance) and precise transmission line simulation and crosstalk analysis are mandatory.

3.Component Engineering & Supply Chain: Rigorous selection of automotive-grade (AEC-Q), industrial-grade, or space-grade components, coupled with full lifecycle management to ensure supply reliability and performance consistency. Derating is applied for critical parts.

4.Thermal Management Design: Optimizes heat dissipation paths through thermal simulation, employing combinations of heavy copper, thermal vias, embedded metal substrates, high-performance heatsinks, and liquid cooling solutions.

5.Design for Manufacturing & Testability (DFM/DFT): Incorporates DFM and DFT rules during the layout phase to ensure the complex design can be produced with high yield and thoroughly validated.

Precision Manufacturing and Stringent Quality Assurance

Manufacturing is the physical realization of the design, demanding precision and repeatable process control:

1.Advanced SMT & Odd-Form Assembly: Employs ultra-high-precision placement equipment (for 01005/0201 components), selective soldering, eutectic die attach, and vacuum reflow to handle complex BGAs, QFNs, and odd-form components.

2.Specialty Process Application: Includes rigid-flex PCB fabrication, RF shielding cavity press-fit/soldering, potting, conformal coating, and underfill processes to meet specific environmental and mechanical stress requirements.

3.Comprehensive Multi-Stage Testing: Implements Automated Optical Inspection (AOI), X-Ray Inspection (AXI), Flying Probe/In-Circuit Test (ICT), Boundary Scan, high/low-temperature environmental functional testing, and extended burn-in testing to ensure "zero-defect" or near-zero-defect delivery.

Key Criteria for Partner Selection

Selecting a high-end PCBA supplier should be approached as choosing a strategic technological extension partner. Key evaluation points include:

⦁ Design & Engineering Capability: Does the partner possess system-level simulation, SI/PI analysis experience, and multi-physics co-design expertise?

⦁ Manufacturing Technology Platform: Does it own production lines capable of handling high complexity (e.g., HDI, heavy copper, rigid-flex) with corresponding process certifications?

⦁ Manufacturing Technology Platform: Does it own production lines capable of handling high complexity (e.g., HDI, heavy copper, rigid-flex) with corresponding process certifications?

⦁ Quality System & Culture: Is it certified to top-tier standards like AS9100 or IATF 16949? Does it have established processes for continuous improvement and root cause analysis?

⦁ Supply Chain Management Depth: Can it manage and guarantee the long-term, traceable supply of critical industrial/automotive-grade components?