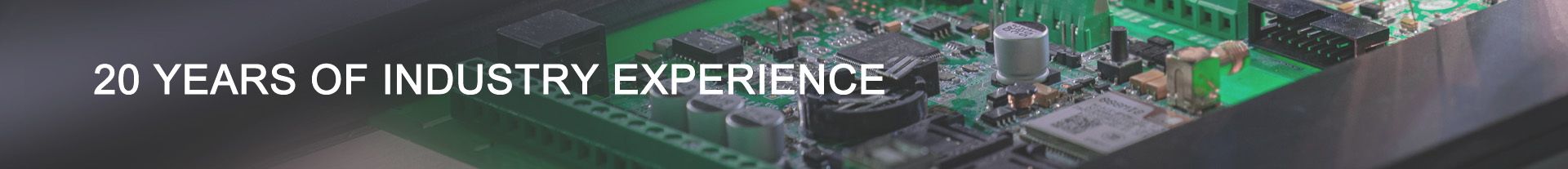

Car Amplifier PCBA Design Guide

The amplifier PCBA is the heart of any high-fidelity car audio system. However, the demanding automotive environment—characterized by voltage fluctuations, extreme temperatures, and mechanical vibration—poses significant challenges to PCBA stability and reliability. Any compromise in signal integrity, power integrity, or thermal management directly translates to degraded audio quality, distortion, or premature failure. This guide explores key design considerations for high-performance car amplifier PCBAs and details how our specialized manufacturing expertise ensures your design success.

一、 Core Design Challenges: Beyond Audio Performance

1.Signal Integrity (SI)

⦁ Car amplifiers process low-level, highly sensitive audio signals. Even minor electromagnetic interference (EMI) or power supply noise, if introduced, becomes amplified at the output, resulting in audible hiss or buzz.

⦁ Key Consideration: Sensitive analog signal paths require strict isolation and shielding from noisy digital circuits (e.g., DSP) and power sections.

2.Power Integrity (PI)

⦁ Amplifiers draw massive transient currents during high-power output. An inadequately designed Power Distribution Network (PDN) on the PCBA can cause voltage sag, leading to dynamic compression or even protective shutdowns.

⦁ Key Consideration: Implement low-impedance power planes and deploy a combination of bulk and low-ESL decoupling capacitors to deliver clean, stable instantaneous power.

3.Thermal Management Strategy

⦁ Inefficient amplifier chips convert a significant amount of electrical energy into heat. Excessive junction temperature is a primary cause of performance degradation and early-life failure.

⦁ Key Consideration: PCBA design must incorporate effective heat dissipation paths using thermal vias, attachment to heatsinks, and selection of high-thermal-conductivity substrates (e.g., metal-core PCBs).

二、Manufacturing Strategies for Automotive-Grade Reliability

1.Material Selection & Stack-up Design

Our engineering team recommends:

⦁ Automotive-Grade Laminates: Use high-Tg FR-4 or specialized metal-core substrates (e.g., aluminum) to ensure mechanical strength and electrical stability under high-temperature hood conditions.

⦁ Robust Stack-up: Employ symmetrical layer build-ups and sufficient copper weights to manage thermal stress and prevent PCB warpage.

⦁ Surface Finish: ENIG (Electroless Nickel Immersion Gold) is recommended for superior solder joint reliability, planarity, and corrosion resistance.

2.Stringent Process Control

We guarantee long-term reliability under vibration and thermal cycling through:

⦁ 3D SPI & AOI: Full-process Solder Paste Inspection and Automated Optical Inspection ensure zero-defect soldering quality.

⦁ X-Ray Inspection: Non-destructive testing for BGAs and hidden solder joints to eliminate hidden faults like voids or poor wetting.

⦁ Environmental Stress Screening: Optional in-circuit testing and burn-in processes to weed out early-life failures.

三、The Value of Partnering with Manufacturing Experts

1.Design for Manufacturability (DFM) Analysis

We provide free DFM analysis to identify risks unique to car amplifier PCBAs before production, including:

⦁ Heatsink mounting hole compatibility and pressure balance.

⦁ Current-carrying capacity and trace width evaluation for high-power paths.

⦁ Impact of component placement on thermal management and vibration sensitivity.

2.End-to-End Engineering Support

Our support goes beyond standard PCBA fabrication:

⦁ Design Phase Consultation: We offer expert advice on EMC/EMI optimization, grounding strategies, and thermal design.

⦁ Prototype Validation Support: Fast-turn prototyping coupled with detailed test reports for design verification.

⦁ Supply Chain Management: Assistance in sourcing automotive-grade certified components, ensuring a stable and reliable supply chain.

Achieving a high-performance, reliable car amplifier PCBA requires marrying precision audio circuit design with resilience against harsh automotive environments. Our manufacturing expertise in automotive electronics ensures your audio design delivers consistent, exceptional performance from blueprint to mass production.